ABOUT TLC

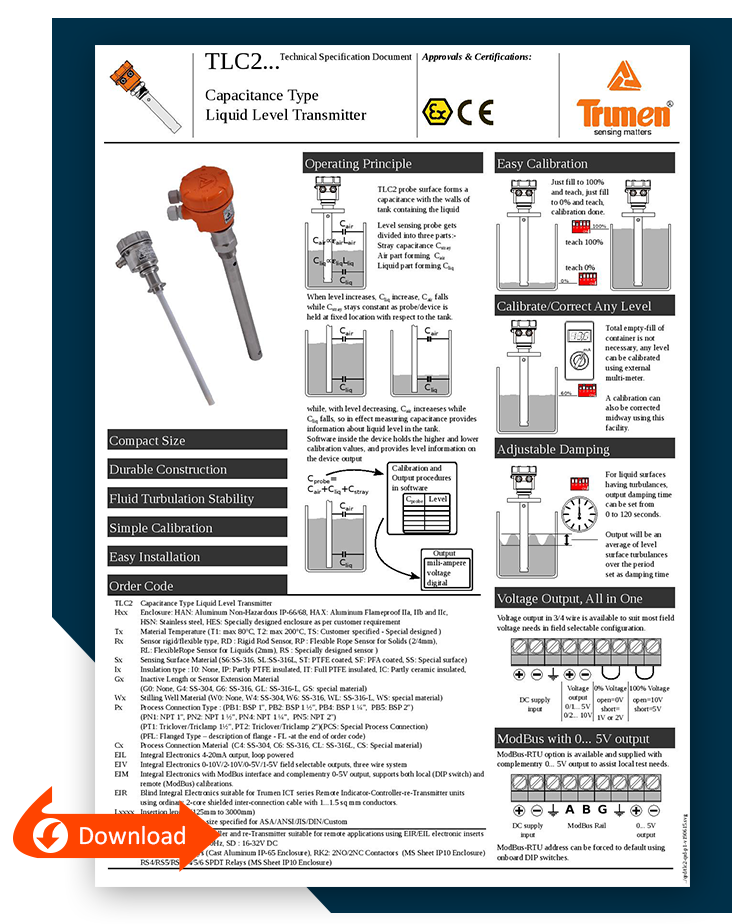

Trumen two wire capacitance type liquid level transmitter model TLC2 being suitable for used in liquids as well as solids, powder, slurry, chemical, edible oil. Trumen TLC2 is a fully, partially & ceramic insulated and used as a robust rod probe and rope probe for level detection of liquids.

Trumen TLC2 can be used with a variety of probes and sensors. It has a two element probe.

ABOUT TRUMEN

Trumen came into existence in 2009 and initially started with manufacturing of Tuning Fork Level Switches for liquid and solid applications.

With time, the manufacturing range increased with addition of Capacitance Level Transmitter & Capacitance Level Switches, RF Admittance Level Switches, Rotating Paddle Level Switches, Conductivity Type Level Switches, Vibrating Rod Level Switches, Hydrostatic Level Transmitter, Radar.

FEATURES

- Trumen capacitance probe compact in size.

- Easy calibration with or without material.

- DC power supply on same terminal(14 to 60VDC).

- Customized process connection threaded / flanged etc.

- Compensation against material build-up.

APPLICATION

-

- Trumen capacitance level transmitter probe is used in different applications like, Free flowing homogeneous liquids like oil, raw water, WFI, DM/DI water etc.

- Suitable for corrosive liquids.

- Process temperature maximum 400°C.

- Operating pressure 20 bar maximum.

OIL

RAW WATER

WFI

DM/DI WATER

OPERATING PRINCIPLE

Operation for TLC

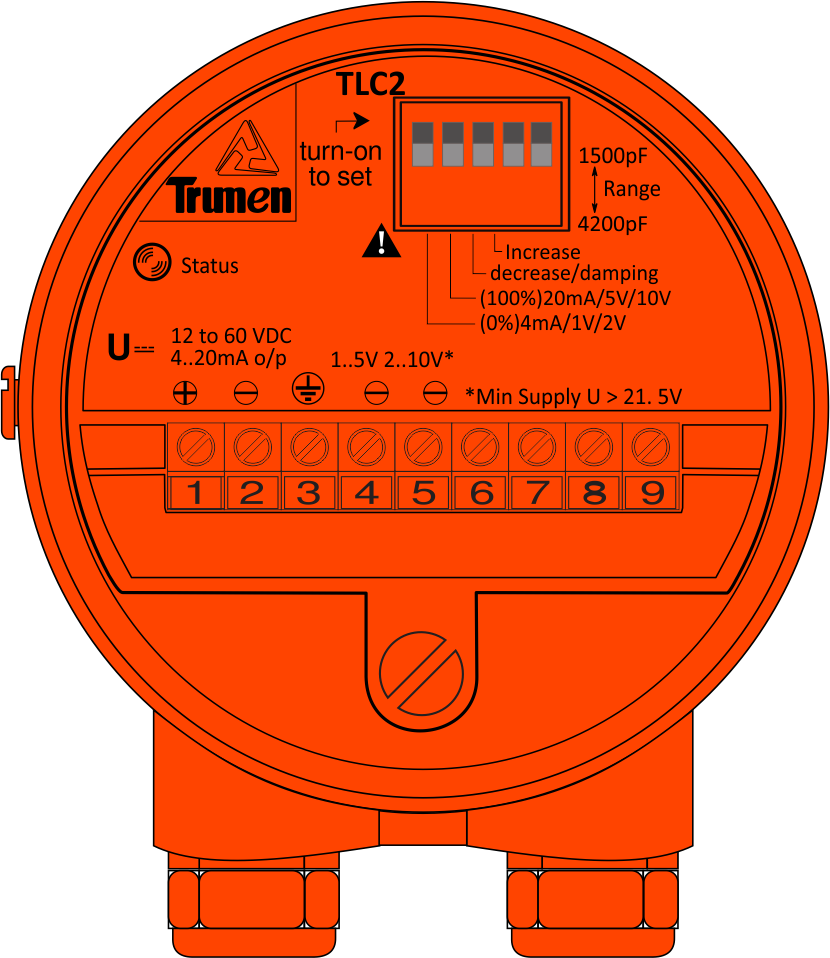

Device operation and settings:

Trumen capacitance level transmitter is very easy to operate-

- Open the cover of Trumen TLC and you can see there are 9 terminals. Terminal 1 & 2 are for 4-20mA loop power supply and terminal 3 is for earth. Terminal 4 is reference negative for 1 to 5V Output at terminal no.2. And terminal 5 is reference negative for 2 to 10V Output at terminal no.2

- There are 5 DIP switches given on connection panel Via DIP

switch no.1 we can calibrate the instrument for 4mA or 0% calibration in air or in material. Via DIP switch no.2 we can calibrate the instrument for 20mA or 100% calibration in air or in material.

Switch no.3 is to set trimming decrease or damping.

Switch no.4 is to set trimming increase.

Switch no.5 is to set range select 1500pF to 4200pF selectable. - Connect the power supply 14 to 60VDC on terminal 1 & 2. Connect the earth on terminal 3 and switch on the power.

- Trumen capacitance level transmitter is ready to calibrate in air or in material, status led blink continuously.

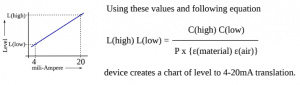

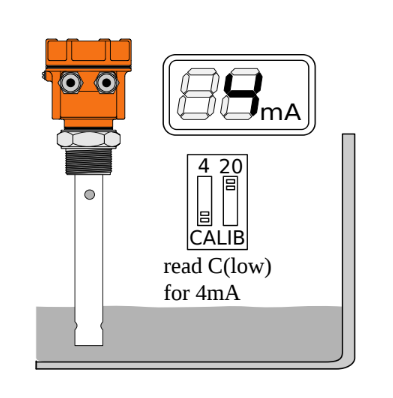

- Now we turned on the switch no.1 to calibrate TLC2 for 4mA or 0% in air or in material. Fill The material at low level status led start blinking once per 2 sec. Millimeter must be connected in series with the device.

Status led blinking faster for 5 sec. Then status LED will start blinking three times then off, successively. mA meter will show 20mA. Wait till mA meter shows 4mA. And status LED glows permanently. - Turned off the switch no.1 4mA level or 0% level is calibrated.

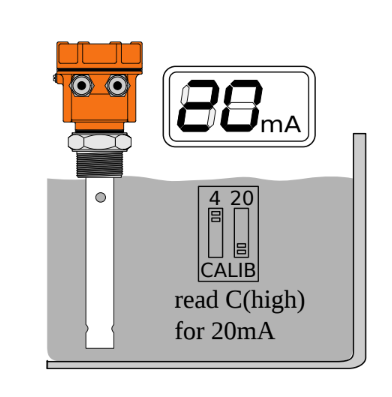

- Now we turned on the switch no.2 to calibrate TLC for 20mA or 100% in air or in material. Fill The material up to the desired level status led start blinking once per 2 sec. MiliAmmeter must be connected in series with the device.Status led blinking faster for 5 sec. Then status LED will start blinking three times then off, successively. mA meter will show 4mA. Wait till mA meter shows 20mA. And status LED glows permanently.

-

Turned off switch the no.2, 20mA level or 100% level is calibrated.

- For 0% or 4mA trimming, turned on switch no.3 or 4 (decrease/increase). Turned on 4mA switch this sequence is important and watch the mili-ammeter till correct trimming of 4mA is done. Immediately turned off switch no.3 or 4 (decrease/increase).Turned off 4mA switch (sequentially).

- For 100% or 20mA trimming, turned on switch no.3 or 4 (decrease/increase). Turned on 20mA switch this sequence is important and watch the mili-ammeter till correct trimming of 20mA is done. Immediately turned off switch no.3 or 4 (decrease/increase). Turned off 20mA switch (sequentially).

- Range switch select for 1500pF or 4200pF can be set via DIP switch no.5. 1500pF is required for oil and water up to 2500mm probe length. 4200pF is required for water above 2500mm probe length.

- You can easily replace the electronics as shown.

Connection Terminals

1 + of DC of 4-20mA Loop

2 – of DC of 4-20mA Loop / Voltage Output +ve

with reference of terminal 4 or 5

Supply:

12 to 60 VDC

3 Earth terminal for safety

4 Reference -ve for 1 to 5V Output at terminal no.2

5 Reference -ve for 2 to 10V Output at terminal

no.2

6 to 9 Not Used

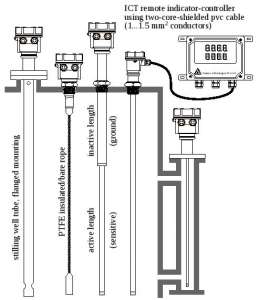

TYPICAL MOUNTING

PRODUCT VIDEO

TECHNICAL DATA & INSTRUCTION MANUAL

TESTIMONIALS

WHAT OUR

HAPPY CLIENTS

SAYS ABOUT US

TRUMEN TLC USERS

UK

UAE

Turkey

Tanzania

Poland

Malaysia

Lithuania

Macedonia

Iran

Italy

Denmark

Chile

France

Japan

Argentina

Kuwait

Canada

Sri Lanka

Korea

Thailand

USA